Welcome To ChemAnalyst

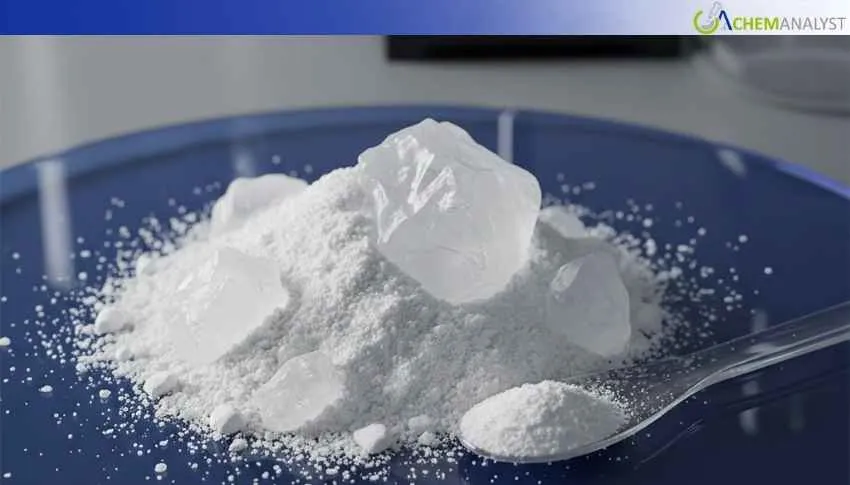

December concluded with China’s Calcium Acetate market gaining 2.4%. This gain was attributed to strong domestic consumption and was complemented by a robust export schedule. The combination of continued purchasing by Southeast Asian agents, strong offtake from pharmaceutical customers, food-preservation companies, and industrial end-users aided this continued performance. Also, while supplies are adequate overall, slight reductions in the supply of Calcium Acetate have appeared because of new environmental compliance requirements and rising feedstock prices; however, these decreases have contributed to the strengthening of prices. Coastal manufacturers are producing near-capacity, while inland manufacturers are operating their tolling units cautiously to maintain equilibrium between supply and demand. The peak shipping season logistics and handling expenses contributed additional support to the offers that have exhibited continued strength. For January, it is anticipated that prices for Calcium Acetate will continue increasing. Market experts have indicated that there will be an increase in prices because manufacturers will be at full capacity and purchasers will resume normal levels of procurement after the holiday break. With stable prices of the raw materials used to produce Calcium Acetate, normal inventories among traders, and a healthy level of business activity anticipated, a very positive outlook can be expected for the Calcium Acetate market early in January.

During December, domestic consumption and healthy external inquiries contributed to the continued upward trend of Calcium Acetate pricing within China. As a result of limited availability in the spot market combined with ongoing Calcium Acetate demand from multiple sectors, an increase was observed during the last week of December.

The overall supply situation for Calcium Acetate is stable; however, it is being controlled, so supply levels are low but stable. Most regional producers based along the coast have been operating at or near full capacity, although inland-based producers are undertaking upgrades to their facilities, and because of this, supply conditions have become slightly tighter. Costs for inputs, including glacial acetic acid and calcium carbonate, have continued to be high during the winter months, creating upward pressure on Calcium Acetate product pricing. The inventory levels maintained by companies primarily located at the...

We use cookies to deliver the best possible experience on our website. To learn more, visit our Privacy Policy. By continuing to use this site or by closing this box, you consent to our use of cookies. More info.