Welcome To ChemAnalyst

EnergyX launches U.S.-based membrane manufacturing, boosting lithium supply chain, reducing reliance on imports, and expanding into carbon capture markets.

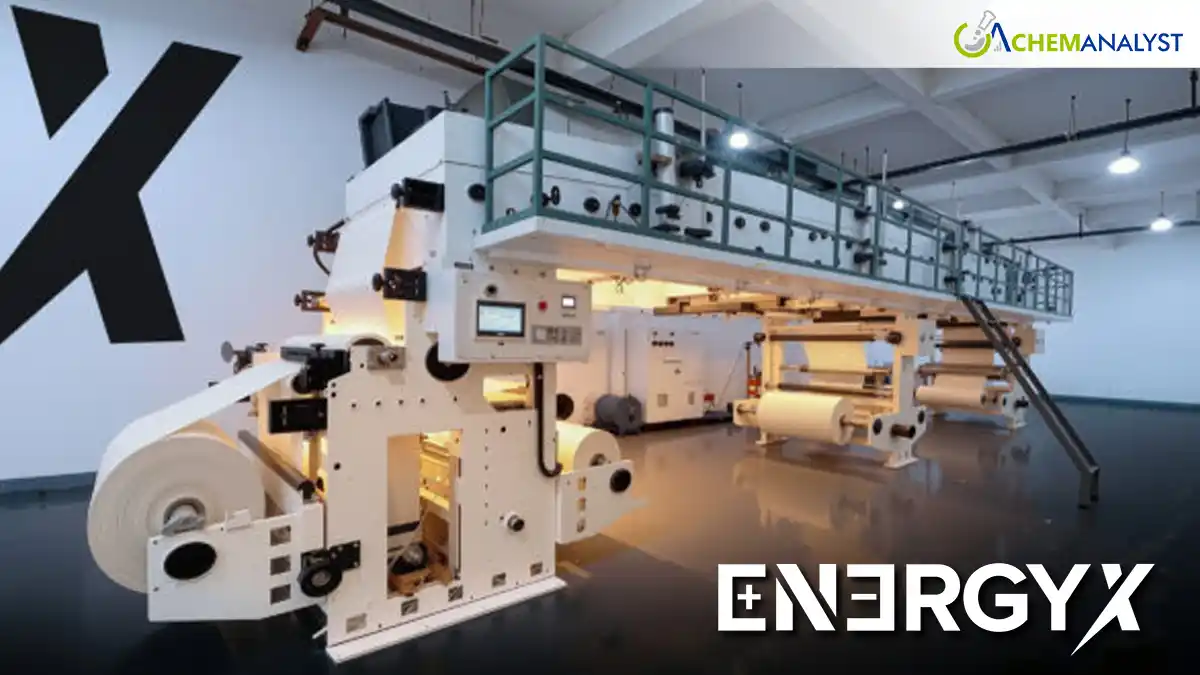

EnergyX, a U.S.-based developer of critical mineral and clean energy solutions founded by CEO Teague Egan, has announced a significant advancement in its industrial capabilities with the commercialization of its advanced materials manufacturing platform. The company has successfully commissioned one of the largest roll-to-roll membrane production machines in North America at its facility in Austin, marking a major milestone in strengthening domestic clean energy supply chains.

This development enables EnergyX to bring a crucial part of its manufacturing process back to the United States, reinforcing the technological backbone required for a secure and scalable domestic lithium supply chain. At the same time, it opens the door to broader applications in high-growth sectors such as desalination, carbon capture, and advanced industrial manufacturing. The operational facility positions the company to serve multiple industries that rely on high-performance separation technologies.

With the manufacturing unit now fully functional, EnergyX has the capacity to internally produce a key component of its proprietary GET-Lit™ lithium separation platform. The facility can generate up to 500,000 square meters of ion exchange membranes annually at industrial scale. This internal production capability significantly reduces dependence on international suppliers while also improving production timelines and operational efficiency.

According to CEO Teague Egan, EnergyX’s long-term vision is centered on vertical integration of its supply chain. By maintaining control over the production of essential consumables used in lithium extraction and recovery processes, the company aims to enhance both performance reliability and cost efficiency. Notably, these proprietary membranes are not limited to lithium applications—they are also in high demand for emerging technologies such as direct air carbon capture, further expanding the company’s commercial reach.

As global demand for lithium and advanced separation materials continues to rise, EnergyX’s vertically integrated model helps mitigate risks associated with geopolitical tensions, supply chain disruptions, and supplier instability. The company’s approach is supported by proprietary chemistries, specialized manufacturing techniques, and trade-secret workflows that create strong barriers to entry for competitors. This strategic advantage is expected to deliver long-term cost savings and operational benefits. For example, EnergyX anticipates reducing execution costs for its flagship Project Lonestar Lithium™ by approximately $10 million compared to relying on third-party suppliers.

Beyond lithium production, EnergyX is evolving into a broader energy technology and advanced materials manufacturing platform. The company is actively expanding into additional sectors, including the nuclear materials supply chain, next-generation battery materials, industrial decarbonization, and water desalination infrastructure. This diversification reflects its ambition to play a central role in multiple segments of the global clean energy transition.

EnergyX has already begun generating commercial traction, securing initial sales across various industry verticals. Looking ahead, the company projects revenues exceeding $100 million over the next five years. Deliveries of its first commercial membrane products and associated equipment are expected to commence in the first quarter of 2026, supported by a growing pipeline of opportunities.

The broader market for ion exchange membranes and electrodialysis systems is projected to reach approximately $7.5 billion by 2035, offering substantial growth potential. With its integrated technology platform and expanding production capacity, EnergyX is well positioned to capture value across both advanced materials manufacturing and complete system solutions.

We use cookies to deliver the best possible experience on our website. To learn more, visit our Privacy Policy. By continuing to use this site or by closing this box, you consent to our use of cookies. More info.