Welcome To ChemAnalyst

BASF's massive Zhanjiang Verbund site in China hit key construction and operational targets, with the Butyl Acrylate (BA) plant starting up ahead of schedule and the steam cracker reaching mechanical completion.

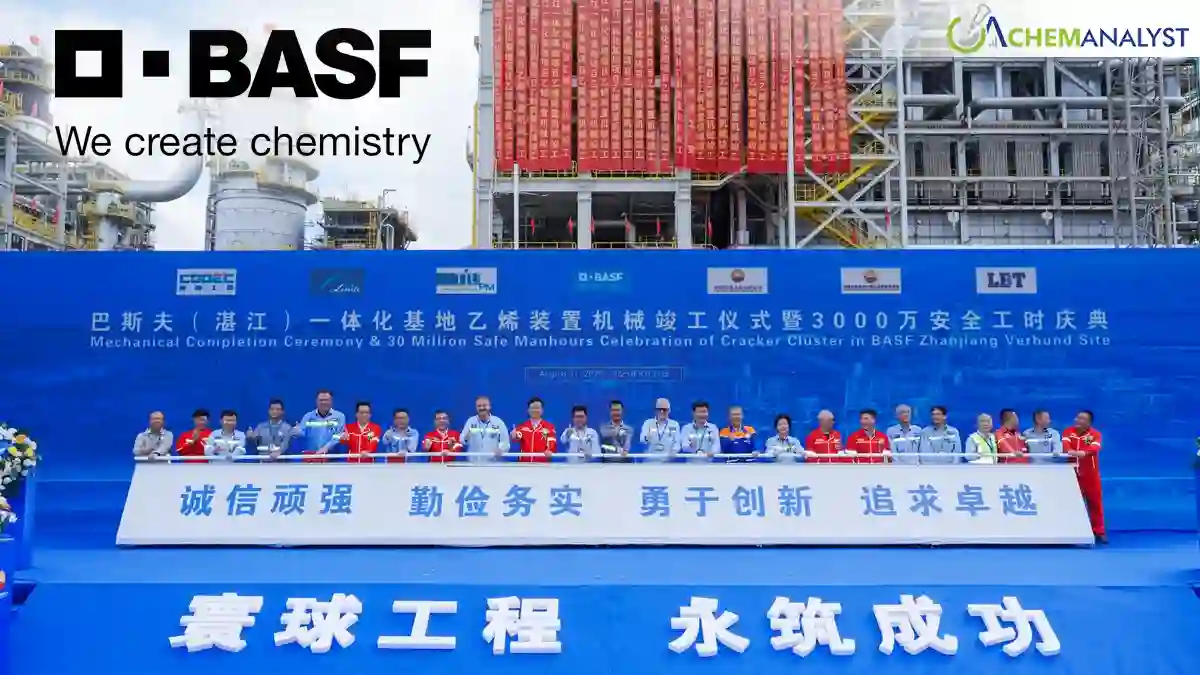

Global chemical giant BASF has announced two significant milestones at its pioneering Zhanjiang Verbund site in Guangdong, China, signaling a major leap forward in the company's strategy to solidify its presence and production capabilities across the Asia Pacific region. The successful start-up of the Butyl Acrylate (BA) plant and the mechanical completion of the steam cracker and its integrated downstream units mark crucial steps toward the site's full operational readiness by the end of 2025.

Butyl Acrylate Plant Operational Ahead of Schedule

The Butyl Acrylate (BA) plant successfully commenced operations on August 11, 2025, impressively ahead of its initial schedule and, critically, with an "exemplary safety record." The plant, which boasts an annual capacity of approximately 400,000 metric tons, has already made its first customer delivery, with the inaugural shipment via tanker trucks successfully delivered on August 17, 2025. This new capacity is poised to reinforce BASF's leading position in the acrylics market, supplying essential materials crucial for sectors such as adhesives, industrial coatings, and architectural coatings.

Following closely behind the BA plant's start-up, BASF confirmed it has achieved mechanical completion for the steam cracker and all associated downstream petrochemical plants. This includes crucial units for ethylene oxide, oxo alcohols, syngas, and high-density polyethylene. The completion of this phase is a pivotal transition, moving the project from intense construction activity to the final stages of operational readiness. Achieving mechanical completion confirms that all plant systems are installed, connected, and tested, paving the way for the scheduled commissioning and start-up activities set to take place by the end of 2025.

The Zhanjiang Verbund site, which will feature a steam cracker with a capacity of one million metric tons of ethylene, is a cornerstone of BASF's commitment to the Asia Pacific market. The integrated nature of the Verbund complex—where production facilities are interconnected to optimize resources, energy, and costs—is expected to significantly enhance BASF's production capabilities and supply chain resilience.

Bir Darbar Mehta, Senior Vice President of Petrochemicals Asia Pacific at BASF, emphasized the strategic importance of the progress: “This world-class integrated site will significantly enhance our production capabilities and supply chain resilience, enabling us to offer a broad portfolio of high-quality, reliable, and competitive solutions... we are well-positioned to fulfill the growing market needs and support our customers’ success with greater efficiency and shorter lead times.”

We use cookies to deliver the best possible experience on our website. To learn more, visit our Privacy Policy. By continuing to use this site or by closing this box, you consent to our use of cookies. More info.