Welcome To ChemAnalyst

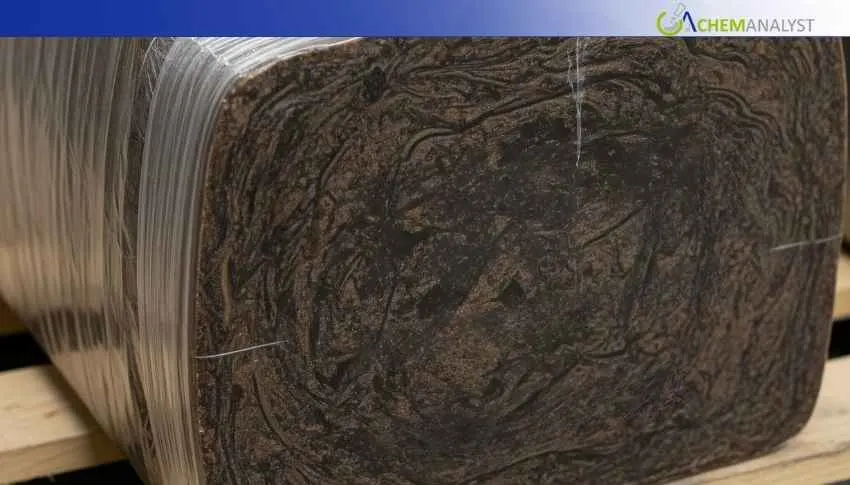

In August 2025, the natural rubber (TSR) market witnessed optimism, largely due to positive dynamics caused by constrained supply and increasing demand. Seasonal factors positively impacted consumption; at the same time, supply was constrained due to difficulties in the major production regions. Buyers appear more optimistic, and logistics movement has improved. The dynamics evolving with constrained supply and decent demand appear to be creating a positive market context; the natural rubber (TSR) community seems to be placing optimistic pressure on expectations to extend positive momentum further.

Key Highlights-

The increase in demand for natural rubber (TSR) from both global and domestic markets increased as the sentiment improved, and the downstream demand grew. Demand for natural rubber (TSR) has entered its traditional peak season, as all-steel tires and heavy-duty trucks&#xx; performance has also spiked. Purchasing interest in natural rubber (TSR) has increased, growing the bullish market sentiment. Material inventory has also reduced in the major importing country, China,...

We use cookies to deliver the best possible experience on our website. To learn more, visit our Privacy Policy. By continuing to use this site or by closing this box, you consent to our use of cookies. More info.