Welcome To ChemAnalyst

During the first half of December 2025, the US EVA market remained relatively flat with a balanced supply-demand scenario due in part to continued production stability. There was little change in market activity; ongoing availability of raw materials and good operation rates at numerous domestic EVA manufacturing sites helped achieve this balance in the market. Seasonal weakness in construction-related products such as adhesives and flooring product lines reduced sales volume for conventional grades of EVA. Still, that decrease was more than offset by continued orders from manufacturers of photovoltaic modules that benefit from government subsidies for renewable energy initiatives. Logistics factors also contributed positively to stable market conditions, with flows of imports from Asia being uninterrupted, freight rates remaining stable, and no weather-related issues in the Gulf Coast region. US inventories at distribution points were deemed adequate and led to no necessity for aggressive inventory replenishment or price adjustments. Most leading producers of EVA continued their regular operations and focused primarily on efficiency and their specialty grades of EVA, supporting their overall business strategies for optimizing their respective product offerings.

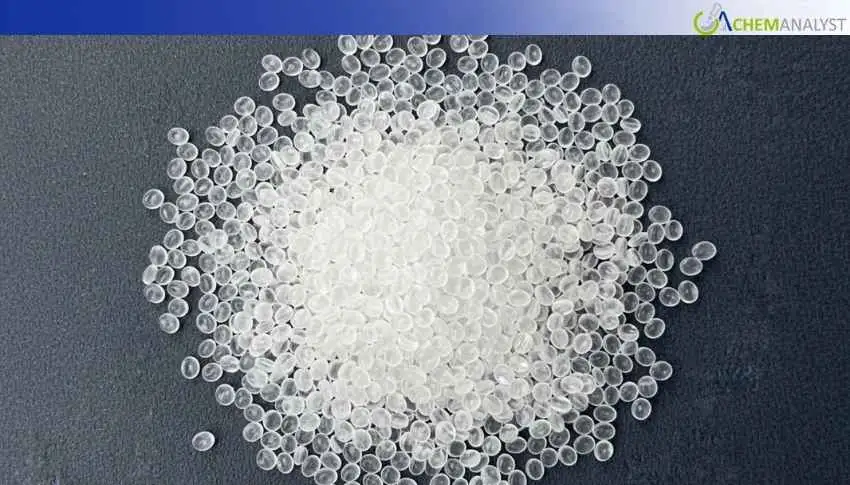

The US ethylene vinyl acetate (EVA) market had a very stable first half of December 2025. There was little price fluctuation, and the supply and demand conditions were balanced in the marketplace, despite the many challenges facing the marketplace in general. According to many of the stakeholders in the market, the balance was primarily caused by the lack of change in the feedstock costs, and due to a seasonal slowdown of the traditional end-use markets, the two factors effectively cancelled one another out and provided a stable market environment. Domestic EVA producers continued to operate continuously, with the downstream segments of the market experiencing mixed offtake patterns.

In December, the dynamics of the market reflected that the domestic chain had an adequate supply. Vinyl acetate monomer (VAM) prices and ethylene feedstock prices did not change much from previous months, so VAM producers didn't feel the increased pressure to increase production costs, and EVA producers continued to supply EVA materials at stable levels for their customers. On the supply side, most resin plants in the US ran at normal production levels without experiencing any major shutdowns during December, providing enough resin for seasonal buyers.

The demand for EVA during the month of December was much less homogeneous. Purchasers were selective in their purchases, noting the same slowdown seen at year-end in the traditional segments of construction adhesives and flooring compounds. This slowdown is usually seen when purchasing agents begin to reduce purchases ahead of closing out a year in retail. On the other hand, the solar sector was interested in the higher-VA grades of EVA because tax incentives for renewable energy in the US have created continued demand for the encapsulant resins used in solar PV modules. towards inventory strategies.

In 2025, major chemical manufacturers continued to face overall portfolio challenges within their businesses, resulting from their EVA participation. Even though some of the larger producers have changed the structure of their operations through the restructuring of certain parts of their business and the evaluation of their strategic assets, these companies are still committed to producing EVA resin because of its broad usage across a wide range of end products and anticipated high volume demand for the near future.

Market analysts predict that for the first half of 2026, the basics of EVA will remain relatively stable. If there is an acceleration of downstream stocking or continuing increases in feedstock costs, some small upward price pressure may appear. Long-term growth should continue to be supported through the growing use of EVA in renewable energy, flexible packaging, and performance materials.

We use cookies to deliver the best possible experience on our website. To learn more, visit our Privacy Policy. By continuing to use this site or by closing this box, you consent to our use of cookies. More info.